Thermal powder-scale modeling of selective laser melting

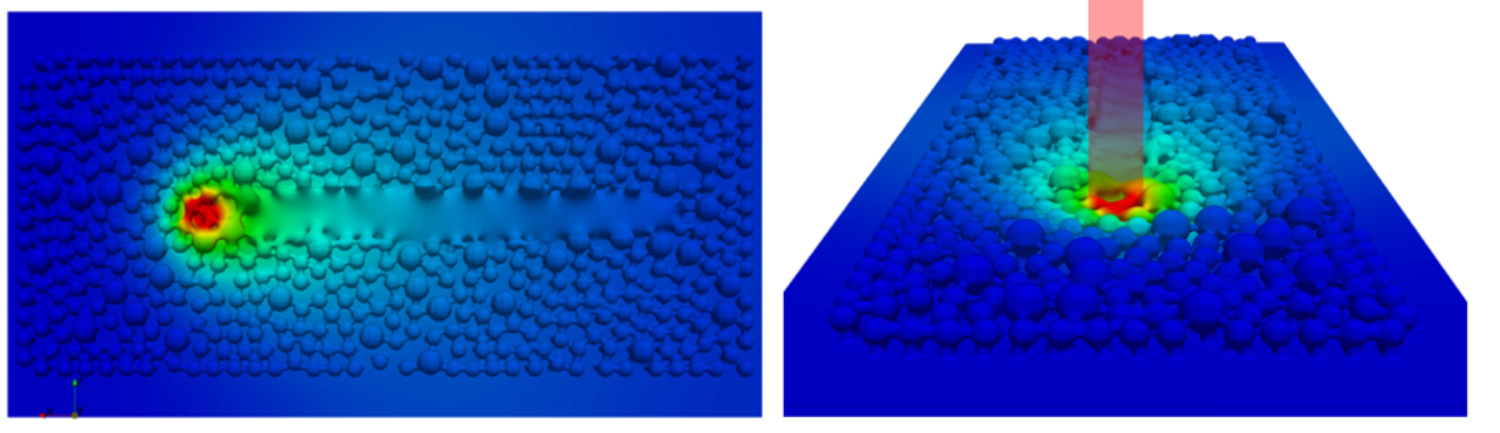

We have recently started working at the modeling and simulation of 3D printing processes. In collaboration with colleagues at the external page TU Braunschweig, we are developing a powder-scale model and the related simulation framework for selective laser melting, an additive manufacturing technology used for the fabrication of metallic components. In the selective laser melting process, a fine layer of material in its powder form is melted by a laser beam. Upon cooling, this layer re-solidifies, and a new layer of powder is spread on it and melted again. This layerwise process is continued until the required three-dimensional part is manufactured. The technology can be especially advantageous and efficient in the production of geometrically complex structures, however, in order to control factors such as presence of defects, mechanical anisotropy and surface roughness of the final parts, the complex physical phenomena involved in the process need to be understood through modeling and experiments. Our end application in this project is manufacturing of suction panels for laminar flow control.